What is Controlled Atmosphere?

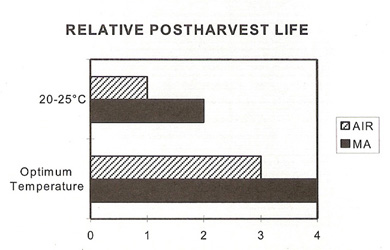

Controlled atmospheres (CA) or modified atmospheres (MA) mean removal or addition of gases resulting in an atmospheric composition around the commodity that is different from that of air (78.08 percent N2, 20.95 percent O2, 0.03 percent CO2). Usually this involves reduction of oxygen (O2) and/or increase of carbon dioxide (C02) concentrations. CA and MA differ only in the degree of control; CA is more exact, providing active control during the entire journey. The use of CA or MA should be considered as a supplement to proper temperature and relative humidity management (Fig. 1).

Benefits and Limitations of Controlled Atmospheres

Benefits

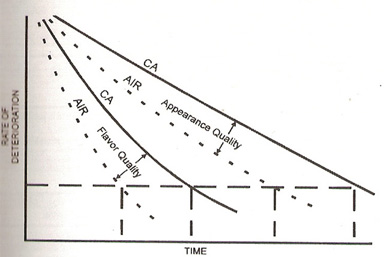

The potential for benefit from CA/MA is dependent upon the commodity, variety or cultivar, physiological age, atmospheric composition, and temperature and duration of storage. CA/MA slow down deterioration of appearance, textural, flavor, and nutritional quality (Fig. 2) and reduce quantitative losses during postharvest handling and storage of horticultural perishables because of the following effects:

- Retardation of senescence (ripening) and slowing down of respiration and ethylene production rates, softening, and compositional changes.

- Reduction of fruit sensitivity to ethylene action at O2 levels less than about 8% and/or CO2 levels greater than 1%.

- Alleviation of certain physiological disorders such as chilling injury of avocado and chili pepper, russet spotting in lettuce, and scald of apples.

- CA/MA can have a direct or indirect effect on postharvest pathogens and consequently reduce decay incidence and severity. For example, elevated C02 levels (10% to 15%) significantly inhibit development of Botrytis rot on strawberries, cherries, and other fruits.

- Low 02 (0.5 percent and lower) and/or elevated C02 (40 to 80%) for short durations, alone or in combination with heat treatments, can be a useful tool for insect disinfestation in some commodities to meet quarantine requirements of importing countries.

Limitations

In most cases, the difference between beneficial and harmful CA/MA combinations is relatively small. Also, CA/MA combinations that are necessary to control decay or insects, for example, cannot always be tolerated by the commodity and may result in faster deterioration. Potential hazards of CA/MA to the commodity include the following:

- Initiation and/or aggravation of certain physiological disorders such as blackheart in potatoes, brown stain on lettuce, brown heart in apples and pears.

- Irregular ripening of fruits such as banana, pear, and tomato can result from O2 levels of less than 2% and/or CO2 levels greater than 5%.

- Development of off-flavors and off-odors at very low O2 concentrations as a result of anaerobic respiration.

- Increased susceptibility to decay when the commodity is physiologically injured by too-low O2 or too-high CO2 concentrations.

- Stimulation of sprouting and retardation of periderm development in some root and tuber vegetables such as potatoes.

CA/MA: Requirements and Recommendations

Fresh fruits, vegetables, and ornamentals vary greatly in their relative tolerance to low O2 concentrations and elevated CO2 concentrations. These are the levels beyond which physiological damage would be expected. These limits of tolerance can be different at temperatures greater than or less than the recommended temperature range for each commodity. Also, a given commodity may tolerate brief exposures to higher levels of CO2 or lower levels of O2 than those indicated. The limit of tolerance to low O2 would be higher as storage temperature and/or duration increases because O2 requirements for aerobic respiration of the tissue increase with higher temperatures. Tolerance limits to elevated CO2 decrease with a reduction in O2 level and, similarly, the tolerance limits to reduced O2 increase with the increase in C02 level.

Harvesting at the proper maturity is clearly a very important factor in achieving maximum produce quality. Immature fruits are subject to moisture loss, shriveling and mechanical damage and are of inferior quality after ripening. Overripe fruits become soft and mealy and lose flavor and aroma soon after harvest. Most fruits reach their best eating quality when allowed to ripen on the plant. A few (avocados, bananas), however, will not ripen well on the plant and must be ripened after harvest. Others (tomatoes, mangos, most stone fruits) are typically harvested before they reach optimum eating ripeness so that they can be transported and distributed before becoming overripe. As fruit ripen they undergo a series of changes that include production of pigments that lead to changes in color, development of flavor and aroma, softening of tissues, breakdown of bitter and astringent compounds, changes in size and shape and development of seeds.

Of the fruits that are eaten ripe one group is known as climacteric fruits. These fruits are induced to ripen rapidly and irreversibly by exposure to mull amounts (typically a few parts per million) of the plant hormone ethylene. Ethylene is produced by ripening plant tissues as well as by combustion, automobile engines, gas or diesel fork lifts, fluorescent light ballasts and some fungi and bacteria. Once induced by ethylene, these fruits will rapidly ripen and must be consumed within days or they will become overripe and lose quality. In some cases, such as tomatoes, bananas and honeydews, fruit are deliberately exposed to ethylene to ensure rapid and uniform ripening. For other fruits, such as kiwifruit and Bartlett pears, ethylene must be rigorously excluded or they will become overripe and unsalable.

Even non-climacteric fruit will ripen more rapidly in the presence of ethylone. However, when ethylene is removed, their ripening will slow. The induction of the ripening process is not irreversible as it is with climacteric fruit. A list of climacteric and non-climacteric fruit is presented in Table 1.

Table 1. Some examples of climacteric and non-climacteric fruits.

| Climacteric Fruits | Non-climacteric Fruits | ||

| Apple | Muskmelon | Blackberry | Lychee |

| Apricot | Nectarine | Cacao | Olive |

| Avocado | Papaya | Cashew Apple | Orange |

| Banana | Passion Fruit | Cherry | Pepper |

| Blueberry | Peach | Cucumber | Pineapple |

| Breadfruit | Pear | Eggplant | Pomegranate |

| Cherimoya | Persimmon | Grape | Raspberry |

| Feijoa | Plantain | Grapefruit | Satsuma Mandarin |

| Fig | Plum | Jujube | Strawberry |

| Guava | Sapote | Lemon | Summer Squash |

| Jackfruit | Soursop | Lime | Tamarillo |

| Kiwifruit | Tomato | Loquat | Tangerine |

| Mango | Watermelon | ||

As mentioned earlier, temperature control is the most effective tool for maintaining produce quality and delaying deterioration. Not all commodities should be kept at the same temperature. Although most should be kept near 0°C (32°F), chilling sensitive tropical or subtropical commodities should normally not be kept at less than 10-13°C (50-65°F). Because the development of chilling injury depends on an interaction of commodity sensitivity, maturity, temperature and time, some chilling sensitive commodities (such as cantaloupes) can be kept at refrigerated temperatures for limited periods of time.

The optimum transport conditions recommended in this handbook are based on the best available information for the specific commodity. In many cases, optimum temperatures and atmospheres may vary depending on the variety or cultivar and growing region for the commodity. For this reason, the recommended conditions are conservative. Most loads of the specified commodity will benefit most of the time under the recommended conditions. In some cases the commodity may tolerate lower O2 or higher CO2 than recommended, especially for short periods of time. For this reason, recommendations include a range of appropriate conditions. If in doubt, set controls to achieve the middle of the recommended range. When experience suggests otherwise, adjust up or down.

Current and potential CA use for long-term storage and transport of fresh fruits and vegetables is summarized in Table 2. Its use on nuts and dried commodities (for insect control and quality maintenance, including prevention of rancidity) is increasing as it provides an excellent substitute for chemical fumigants (such as methyl bromide) used for insect control in some commodities. Also, the use of CA on commodities listed in Table 2 other than apples and pears is expected to continue to increase as international market demands for year-round availability of various commodities expand.

Fig. 1 Relative postharvest life of fresh produce kept in air or modified atmosphere (MA) at room temperature (20-25°C) or at optimum temperature (near 0°C except for chilling-sensitive commodities that should be kept at 5 to 14°C, depending on the commodity); from Zagory and Kader (1988).

Fig 2 . Controlled atmospheres slow down deterioration of appearance and flavor quality of fresh produce. Note that postharvest-life based on flavor is shorter than that based on appearance quality.

CA/MA use for short-term storage and transport for fresh horticultural crops (Table 3) will continue to increase supported by technological developments in transport containers that permit use of marine instead of air transport.

CA/MA conditions can replace certain postharvest chemicals used for control of some physiological disorders, such as scald on apples. Furthermore, some postharvest fungicides and insecticides can be reduced or eliminated where CA/MA provides adequate control of postharvest pathogens or insects.

CA/MA may facilitate picking and marketing more mature and more ripe (Better flavor) fruits by slowing their postharvest deterioration to permit transport and distribution. Another potential use for CA/MA is in maintaining quality and safety of fresh-cut (lightly-processed) fruits and vegetables, which are increasingly being marketed as value-added, convenience products.

The residual sidual effects of CA/MA on fresh commodities after transfer to air (during marketing) may include reduction of respiration and ethylene production rates, maintenance of desirable color and firmness, and delayed decay. Generally, the lower the concentration of O2 and the higher the concentration nitration of CO2 (within the tolerance limits of the commodity), and the longer the exposure to CA/MA conditions, the more prominent are the residual effects.

In some cases CA/MA may not extend the storage time but may still confer benefits such as preventing chilling injury or maintaining firmness of some fruits.

Table 2. Summary of use for long-term storage of fresh fruits and vegetables.

|

Storage duration (Months) |

Commodities |

| More than 12 |

Almond, Brazil nut, cashew, filbert, macadamia, pecan, pistacio, walnut, dried fruits and vegetables. |

| 6-12 |

Some cultivars of apples and European pears. |

| 3-6 |

Cabbage, Chinese cabbage, kiwifruit, some cultivars of Asian pears, persimmon, pomegranate. |

| 1-3 |

Avocado; banana, mango, grape, (no SO2), cherry, some peach, nectarine, and plum cultivars; olive. |

Table 3. Summary of CA/MA use for short-term storage and/or transport of fresh horticultural crops.

| Primary benefit of CA/MA | Commodities |

| Delay of ripening and avoiding chilling temperatures |

Avocado, banana, mango, melons, nectarine, papaya, peach, plum, tomato (picked mature-green or partially ripe). |

| Control of decay |

Blackberry, blueberry, cherry, fig, grape, raspberry, strawberry. |

| Delay of senescence and undesirable compositional changes (including tissue brown discoloration) |

Asparagus, broccoli, lettuce, sweet corn, fresh herbs, fresh-cut (lightly processed) fruits and vegetables. |

ООО «Транстек» - Рефконтейнеры.рф ®