Optimum Relative Humidity: 90-95%

Benefits of CA: Low O2and elevated CO2reduce color loss and discoloration following mechanical injury.

Benefits of Ethylene Removal: Beans produce very little ethylene. However, ambient ethylene can cause yellowing so sources of ambient ethylene should be excluded.

Special Treatments Before Shipping: Beans lose moisture rapidly and so should be cooled rapidly after harvest and kept at high humidity. Ensure adequate air flow through the beans during shipment to help prevent growth of molds. The discoloration of broken beans awaiting processing can be reduced by holding them in 20-30% CO2 and 8-10% O2 for 24 hours.

Varietal Differences: Bean cultivars may differ significantly in their sensitivity to chilling. Some cultivars may be held in CA at temperatures as low as 5°C. Others will experience chilling injury at less than 7.2°C.

Mixed Loads: Snap beans are sensitive to ethylene and so should not be shipped with commodities that produce ethylene. They are chilling sensitive and should not be shipped at temperatures less than 4°C.

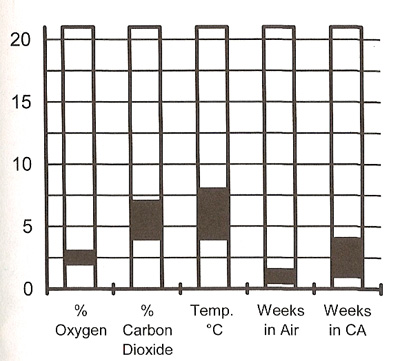

Cautions: O2less than 2% can cause off-flavors. CO2greater than 7% can also cause off-flavors. Snap beans are chilling sensitive and the degree of sensitivity varies by cultivar. The symptoms of chilling injury, surface pitting and russeting, appear after the beans have been held at room temperature after removal from chilling temperatures. The russeting is aggravated by free moisture. Wherever possible, high humidity should be maintained without allowing free moisture to condense on the beans. Preventing temperature fluctuations will help prevent condensation of moisture.

ООО «Транстек» - Рефконтейнеры.рф ®